Gas Oil Steam Boiler

Gas Oil Steam Boiler

- Capacity :10ton,12ton,15ton,20ton

- Pressure :1.0 MPa~ 4.9 MPa

- Fuel :Heavy oil, diesel, natural gas, LPG, etc.

- Application : Textile mill, paper plant, food industry, laundry, hotel, etc.

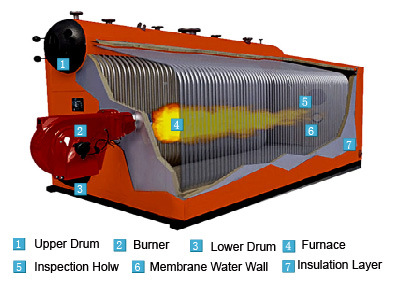

- Brief Intro :SZS series water tube boiler has double drums, and arranged as “D” shape, adopts membrane cooling wall, has the characteristics of high steam quality, sufficient output, and high thermal efficiency (97%), etc.

- Email: [email protected]

- INQUIRY

The structure of SZS gas & oil water tube boiler is arranged as drum longitudinal type “D” shape,  it’s quickly assembled boiler with water tube, has the characteristics of high steam quality, sufficient output, high thermal efficiency, etc. The structure of furnace water cooling wall and convection gas pass is membrane wall, have good sealability, and effectively reduce refractory brick quantity and maintenance workload. The layout of economizer at boiler tail could effectively reduces exhaust gas temperature and improve boiler thermal efficiency. This series gas fired water tube boiler is delivered as whole when leave factory, convenient for transportation, and has a short install period. Jinzhen Boiler has a mature R&D and design team, could customize the boilers based on customers’ requirement.

it’s quickly assembled boiler with water tube, has the characteristics of high steam quality, sufficient output, high thermal efficiency, etc. The structure of furnace water cooling wall and convection gas pass is membrane wall, have good sealability, and effectively reduce refractory brick quantity and maintenance workload. The layout of economizer at boiler tail could effectively reduces exhaust gas temperature and improve boiler thermal efficiency. This series gas fired water tube boiler is delivered as whole when leave factory, convenient for transportation, and has a short install period. Jinzhen Boiler has a mature R&D and design team, could customize the boilers based on customers’ requirement.

Application

SZS series oil gas water tube steam boiler is widely used for industrial production which has large steam requirements. The hot water boiler is used for offering hot water to hotel, school, laundry, gym, farm, etc.

1) Textile industry - dyeing machine, drying rooms, high temperature machine, resin setting machine.

2) Food industry - cooking, drying, vegetable oil refining.

3) Chemical industry - oil chemistry, polymer industry, reaction tanks, distillation, concentration.

4) Plastics industry - plastics fired, extruded shape.

5) Rubber industry - hot press, hot extent, extrusion, vulcanization molding, injection, etc.

6) Paper industry - drying, corrugated paper processing, calender, glue roller.

7) Wood industry - hot processing, heat setting.

8) Forest products industry - plywood, polystyrene board, fibreboard heating setting.

Technical Advantages

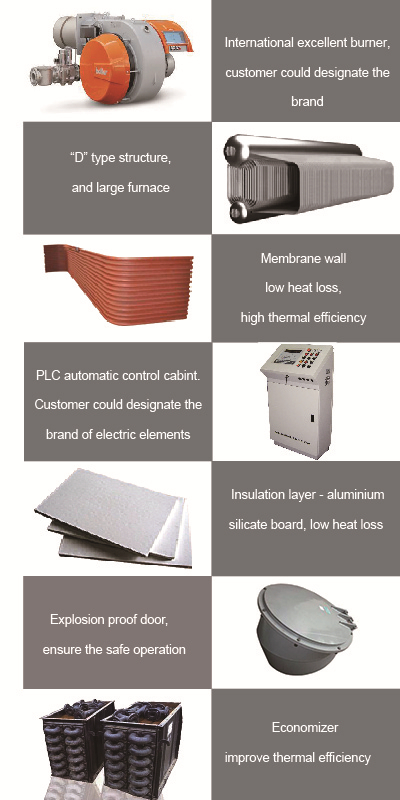

1. “D” shaped layout

Adopts double drums and “D” type structure, large combustion chamber, good flame fullness degree, sufficient combustion. The boiler has a sufficient output, and excellent overload capacity. Compact structure, covers a small area.

2. Membrane Wall Structure

The furnace adopts membrane cooling wall, and equipped with inner board with whole sealing welding structure, low heat loss, high thermal efficiency.

3. Good Thermal Insulation Property

The boiler shell uses aluminium silicate board for heat preservation, high thermal shielding efficiency, low heat loss, increase the boiler thermal efficiency.

4. Automatic Control

1) Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

2) Adopts international brand burner, operate automatically, high combustion efficiency, low harmful gas emission and noiseless operation.

5. Safe Operation

1) Equipped with two explosion door at the furnace roof, to ensure the boiler operate safety and efficiently.

2) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

3) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, and safety valve, etc.

6. Convenient Maintenance

1) There are manhole and inspection hole on the boiler, convenient for boiler internal installation, inspection and clean.

2) Membrane wall effectively reduce refractory brick quantity and maintenance workload.

Technical Specification

| Model | Rated Evaporation | Rated Steam Temperature | Working Pressure | Water Supply Temperature | Heating Area | Overall Dimension |

| (t/h) | (℃) | (Mpa) | (℃) | (㎡) | (mm) | |

| SZS10-1.25-Y(Q) | 10 | 194 | 1.25 | 20 | 340.23 | 8500×5865×4670 |

| SZS15-1.0-Q | 15 | 184 | 1 | 104 | 632.99 | 7970×4628×3470 |

| SZS20-1.25-Y(Q) | 20 | 194 | 1.25 | 105 | 556.64 | 12220×6895×4465 |

| SZS25-2.45-Y(Q) | 25 | 225 | 2.45 | 105 | 714 | 10860×70000×4850 |

| SZS30-1.25-Y(Q) | 30 | 194 | 1.25 | 105 | 767 | 12900×7000×4850 |

| SZS35-2.45-Y(Q) | 35 | 225 | 2.45 | 105 | 958 | 12910×7000×4850 |

| SZS50-2.45-Y(Q) | 50 | 225 | 2.45 | 105 | 1230 | 13200×12000×4700 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||

Categories

Contact Us

Tel:+86 158 3808 8573

Fax :+86 371 5596 3948

Mobile:+86 158 3808 8573

E-mail: [email protected]

Skype: 15838088573

Whatsapp: +86-15838088573