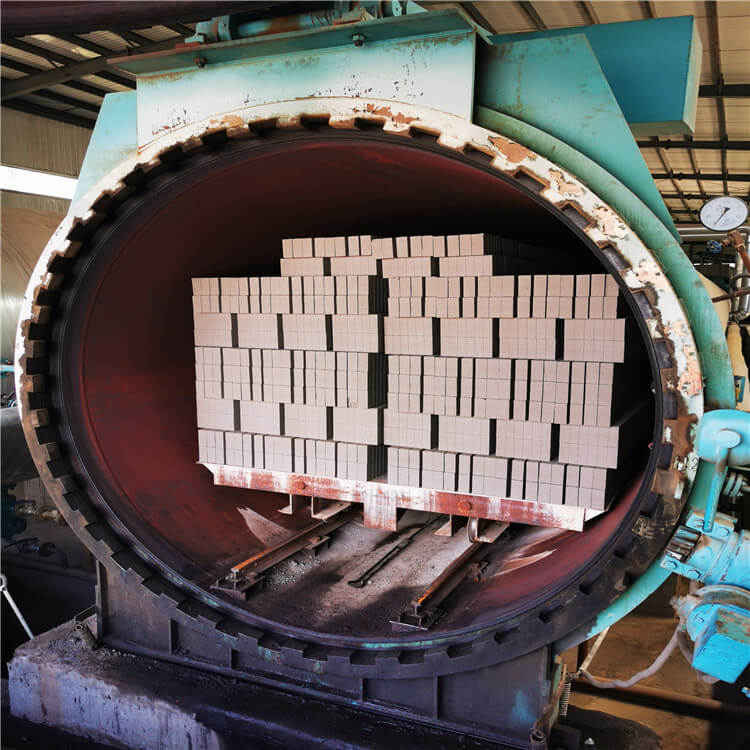

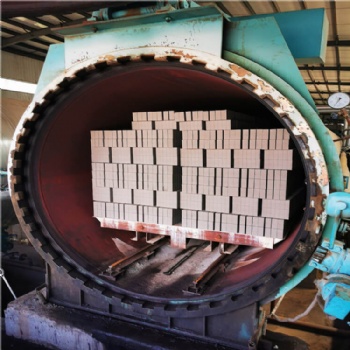

Autoclave Kettle

Fly Ash Brick Curing Autoclave Kettle

- Design Pressure :1.0-3.8 Mpa

- Design Temperature :187-225°C

- Application: Autoclave Kettle belongs large pressure vessel equipment, used for maintenance and steaming of lime-sand brick, fly-ash brick, aerated concrete blocks, new light wall material, and concrete tubular pile and other building products.

- INQUIRY

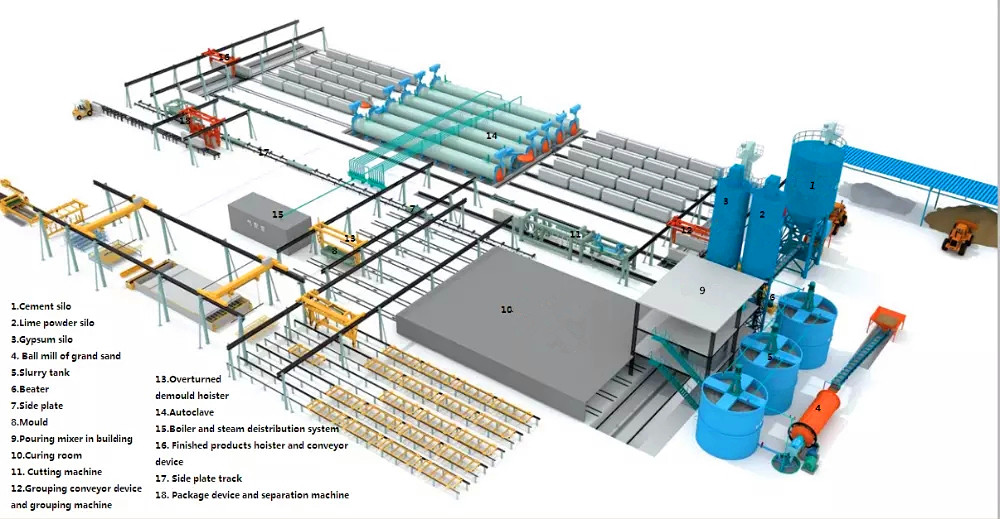

Steam autoclave kettle, also known as autoclave, is a large volume, heavy weight of large pressure vessels.The autoclave is widely used in the autoclavate curing of aerated concrete blocks, concrete pipe piles, grey sand bricks, coal ash bricks, microporous calcium silicate boards, new lightweight wall materials, insulating asbestos boards and other building materials, and the hydrothermal reaction of Cao -- Si02 -- H2O is completed in the autoclavate.

Structural features

The autoclave of aerated concrete is a horizontal cylindrical device made of steel. The cap of the autoclave is made of 16MnR steel plate, and the cap flange and body flange of the autoclave are forged by 16MN.The welds of the compression parts are heat-treated and nondestructive tested in accordance with relevant standards.The maximum design pressure can reach 1.65mpa.

Type of autoclavate vessel

Class I or Class II materials for main pressure components: The cap of the simplified autoclavate adopts 16MnR steel plate, which conforms to GB6654 standard.The body flange and the cap flange of the kettle are forged with 16Mn as a whole. The forgings are in accordance with JB4726 2000 standard autoclavate standard standard || level regulations, and ultrasonic nondestructive testing is carried out one by one. The indexes are in accordance with the corresponding regulations of JB/T4730.3-2005.

The main part of autoclave is mainly composed of autoclave body device, autoclave cover device, swing device, hand speed reducer, safety device, support, insulation layer, sealing device, pipe valve instrument and so on.Auxiliary part includes drainage device and electric control box.

1. autoclave body device

it is mainly welded by the tank body and tank body flange.The bottom of the autocalve is paved with rails, which can be used to walk or park the steaming and raising car.Various pipe seats and nozzles are arranged on the kettle body for steam inlet and discharge, condensate water discharge and installation of various valve instruments.

2. Kettle cap device

It is mainly made of welding of kettle cap flange, umbrella tooth plate and ball cap head;The flange teeth of the kettle cover coincide with the flange teeth of the kettle body to close the autoclave.

Swing device

(1) Side door: it is composed of spindle, cantilever beam, support plate, pull plate, pull rod, etc.It is installed on the top of the kettle end and connected with the lifting handle of the kettle cover through the pull rod to lift the functions of the suspension and rotary kettle cover devices.

(2) Upper door: it is composed of heavy box, swinging arm, support plate, etc., to make the kettle cover swing up and down.

4. Hand-operated gear reducer

Fixed on the flange side of the kettle body, it drives the kettle cover to rotate around the central axis by means of the gear plate, so that the teeth of the kettle body and the kettle cover flange can be yi closed or detach.

5. Manual safety device

The manual interlock device is fixed on the flange side of the kettle body and consists of safety handle, sleeve, connecting rod and ball valve, etc.

6. Support

Used as a support kettle body, which is composed of intermediate support, movable support and end support, etc.In addition to the middle support fixed, the rest support with the help of rollers, when hot expansion and cold contraction along the axial movement.

7. Insulation layer

reduce heat loss during autoclave use (the thickness of the autoclave shall be determined by the user according to the nature of thermal insulation materials, and the thermal insulation of the autoclave shall be taken care of by the user).

8. Sealing device

it is composed of rubber sealing ring, globe valve and steam intake elbow.The rubber sealing ring is embedded in the flange sealing groove of the kettle body. During operation, the sealing ring enters into the sealing groove to adhere to the end face of the kettle cover to achieve sealing effect.

9. Valve instrument

including pressure gauge, safety valve, thermometer, thermocouple, ball valve, etc., used to observe the operation of autotroph.

10. Drainage device

it is composed of drainage pipe connector, drain trap, drain valve, etc.Condensed water in the connector will be discharged by the drain trap to avoid solid can block the drain trap;The drain valve can discharge condensate and sludge regularly or irregularly.

11. Electrical safety interlock device

including control cabinet, pressure controller (or electric contact pressure gauge), kettle lock lock device and pressure alarm device, etc., meet the requirements of TSG R0004 "Fixed Pressure Vessel Safety Technical Supervision Regulations" article 3.20, to ensure the safe use of autoclapper.

Categories

Contact Us

Tel:+86 158 3808 8573

Fax :+86 371 5596 3948

Mobile:+86 158 3808 8573

E-mail: [email protected]

Skype: 15838088573

Whatsapp: +86-15838088573