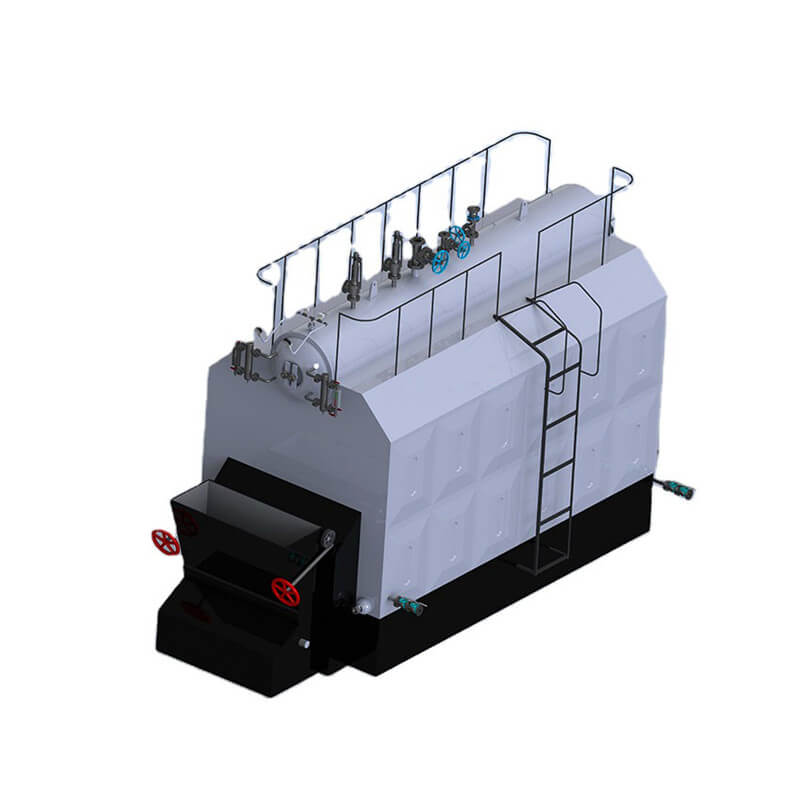

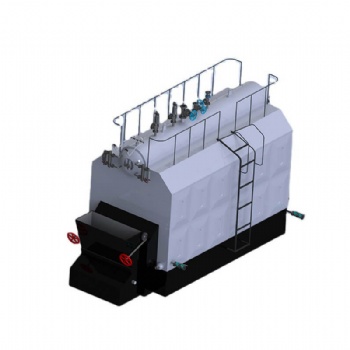

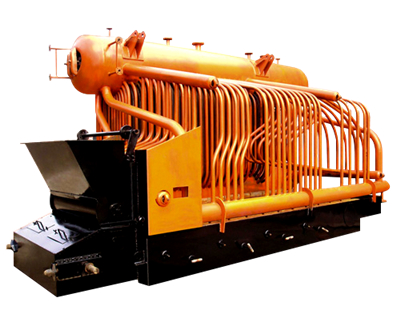

Coal Wood Steam Boiler

Double Drum Steam Boiler

- Model:SZL Series Coal / Biomass Boiler

- Structure:Water Tube Double Drum

- Fuel:Coal, Biomass, Wood, Chip, Husk, Sawdust, Jute, Shell, Waste Solid Fuel etc.

- Capacity: 4 - 25 ton

- Pressure:1.25/1.6/2.5 Mpa (12.5Bar/16Bar25Bar)

- Temperature:194/204/225 C

- Application:Rice Mill,Chemical,Paper Mill,Sugar Mill,Textile Mill,Rubber Plant etc

- INQUIRY

SZL assembly double drum water tube steam boiler is horizontal type large capacity water tube boiler with high steam quality.  Compare with the previous boiler, the new type SZL boiler adopts membrane water cooling wall, low thermal inertia design, and water cooling combustion chamber. Except coal, wood chips, the SZL series boiler could burn other biomass fuel as well, such as bamboo chips, straw, rice hull, peanut shell, bagasse, cotton stalk, coconut shell, corncob, waste cloth, etc. The source of solid biomass fired boiler fuel is widespread, has the advantages of low cost, environmental friendly (sulfur content<0.06%, and zero CO2 emission), energy saving, and high combustion efficiency (>90%).

Compare with the previous boiler, the new type SZL boiler adopts membrane water cooling wall, low thermal inertia design, and water cooling combustion chamber. Except coal, wood chips, the SZL series boiler could burn other biomass fuel as well, such as bamboo chips, straw, rice hull, peanut shell, bagasse, cotton stalk, coconut shell, corncob, waste cloth, etc. The source of solid biomass fired boiler fuel is widespread, has the advantages of low cost, environmental friendly (sulfur content<0.06%, and zero CO2 emission), energy saving, and high combustion efficiency (>90%).

Boiler with steam capacity lower than 4t/h is fast assembly water tube structure, the boiler with steam capacity between 6~25t/h is consisted of upper part (boiler heating part) and lower part (combustion equipment). This series boiler has reached the international advanced level on technology and performance, has the advantages of compact structure, convenient installation, short install period, low cost, and environmental protect.

Application

SZL series double drum steam boiler is widely used in industries, such as textile plant, rice mill, garment factory, utility

or power plant, etc. The relevant capacity hot water boiler is widely used in hospital, hotel, school, farm, etc.

Technical Advantages

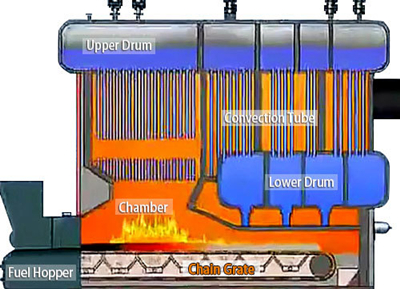

1. Advanced arch design

1) Furnace arch adopts advanced design, forming obvious inverse “α” flue gas flow, which makes the boiler strong adaptability of different fuels.

2) The front and back arches are “wet arch” structure, keep a constant temperature and protect the arch.

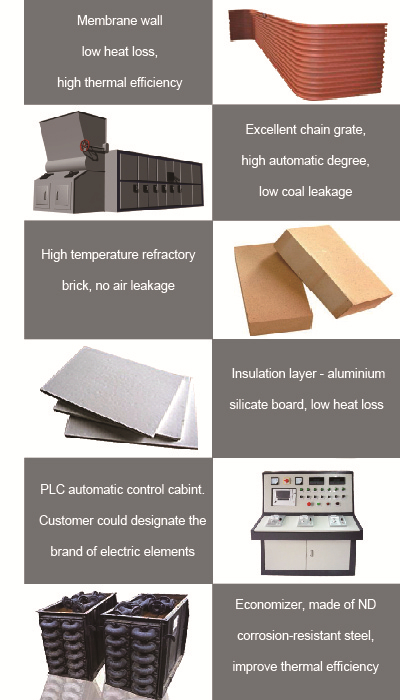

2. Membrane water wall

1) The boiler body use membrane water wall structure, good sealing, low heat lose.

2) Adopts water cooling combustion chamber, increase the radiant heating area, improve the output and thermal efficiency.

3. Excellent chain grate

1) The grate is 500~1000mm longer than others, the fuel combustion time is longer,

improve the combustion efficiency.

2) The small scale flake grate could resist the temperature as high as 1200℃, long working life.

3) The chain grate has a low coal leakage because of the small gap.

4) High automatic degree, decrease labor cost.

5) Convenient for maintenance, it could be done without boiler shut down.

4. Anti Coking Measures

1) The left and right headers are designed as anti-coking headers.

2) Adopts unique double secondary air design, improves the ignition condition of biomass fuel, sufficient air supply to make sure the high combustion efficiency, and avoid fuel coking.

5. Sufficient output

The boiler is equipped with double drums, membrane water wall, and large diameter furnace, the radiant heating area increases more than 50%, achieves sufficient output.

6. Low thermal inertia insulating layer

The boiler shell use light aluminum silicate board for heat preservation, low thermal inertia, and low heat loss. The temperature of furnace rise up quickly.

7. Both sides air inlets

Boiler adopts bilateral air inlets and independent wind chambers, could adjust wind volume and pressure flexible, to ensure the sufficient combustion.

Technical Parameter

| Model | SZL4 | SZL8 | SZL10 | SZL15 | SZL20 | SZL25 |

| Rated Steam Capacity (t/h) | 4 | 8 | 10 | 15 | 20 | 25 |

| Rated Working Pressure(Mpa) | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 |

| Feed Water Temperature (℃) | 20 | 20 | 60 | 105 | 105 | 105 |

| Steam Temperature (℃) | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 |

| Body Heating Area (m) | 96.5 | 177 | 228 | 311 | 727 | 920 |

| Grate Area(m) | 5.5 | 10.4 | 11.8 | 17.7 | 20.8 | 25.8 |

| Fuel Type | Second-class Bituminous Coal, Meagre Coal, Biomass etc | |||||

| Combusion Method | Chain Grate | |||||

| Overall Dimension (m) | 7.6×2.9×3.5 | 7.1×3.3×3.5 | 7.8×3.2×3.5 | 9.5×3.3×3.5 | 11.6×3.2×3.5 | 11.7×3.6×3.5 |

| Weight of Biggest Part (t) | 36.6 | 33 | 35 | 40 | 45 | 50 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||

Categories

Contact Us

Tel:+86 158 3808 8573

Fax :+86 371 5596 3948

Mobile:+86 158 3808 8573

E-mail: [email protected]

Skype: 15838088573

Whatsapp: +86-15838088573