Coal Wood Steam Boiler > Coal steam boiler >

Solid Fuel Fired Boiler

- Capacity :4t/h-20t/h

- Pressure :1.0Mpa-1.6Mpa

- Fuel :coal, wood, straw, bagasse, rice husk, and other solid fuels

- Application : Textile plant, wood factory, rice mill, farm, hotel, school, etc.

- INQUIRY

DZL Series solid fuel fired boiler is drum boiler with both water tubes and fire tubes, the combustion equipment is chain grate (small scale flaker is available), has the advantages of feed mechanically, strong adaptability of different fuels, low coal leakage, and convenient maintenance. The solid fuel includes coal, wood chips, rice hull, bagasse, straw, peanut shell, mustard stalk, cotton stalk, coconut shell, and waste cloth, etc. The source of solid biomass fuel is widespread, it is renewable green energy with the advantages of low cost, environmental friendly (sulfur content<0.06%, and zero CO2 emission), energy saving, and high combustion efficiency (>90%).

Application:

DZL series coal fired chain grate steam boiler is widely used in industries, such as chemical industry, textile plant, rice mill, garment factory, utility or power plant, hospital, hotel, food & beverage, diaries, schools, chemical industry and many other applications. Hot water is usually used in farm, hotel, school, hotel, gym, etc.

Performance Advantages

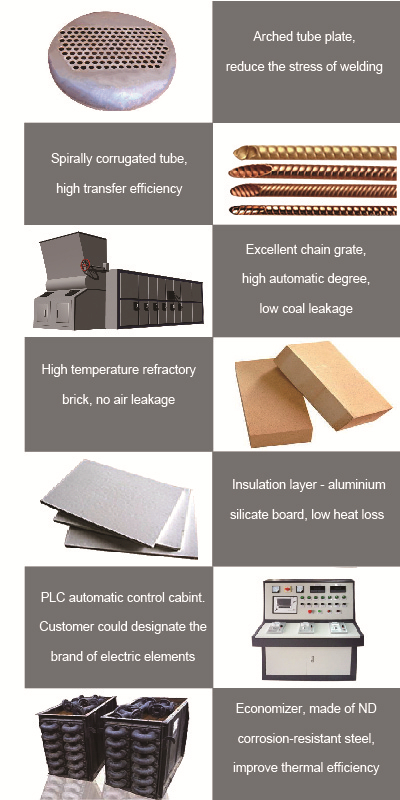

1. Excellent chain grate

1) The small scale chain grate boiler could resist the temperature as high as 1200℃, long working life.

2) The chain grate has a low coal leakage because of the small gap.

3) High automatic degree, decrease labor cost.

4) Convenient for maintenance, it could be done without boiler shut down.

5) For the solid fuels with high humility, increase the length of preheating section of chain grate, to dry the fuels before burning, increase combustion efficiency.

2. High thermal efficiency

2. High thermal efficiency

1)The spirally corrugated tube strengthen the heat transfer, improve thermal efficiency. The flue gas has the foundation of disturbance, avoid ash depositing in tube.

2)The furnace wall was poured entirely by the heat-resistance concrete and high-temperature-resistance refractory brick, and the boiler shell use aluminium silicate board for heat preservation, low heat loss.

3) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, increase thermal efficiency.

3. Anti coking

1) For the easy coking biomass fuels, increase the size of furnace, large space to achieve sufficient combustion.

2) Adopts unique double secondary air design, improves the ignition condition of biomass fuel, sufficient air supply to make sure the high combustion efficiency.

4. Avoid bulging

The riser tube bundle under the drum, remove the dead water region at the bottom of drum, sludge is not easy for depositing, the high temperature area of drum has better cooling, prevent bulging.

5. Avoid tube plate cracking

1) The boiler adopts arched tube plate and spirally corrugated tube, change the quasi-steel body into quasi-elastic body structure, reduce stress, solves the problems of tube plate cracking.

2) Arrange two sides gas duct in drum, the smoke gas could enter into the front smoke chamber smoothly, the temperature of tube plate is lower than 600℃, avoid cracking leaded by high temperature.

6. Sufficient output

Adopts horizontal type three pass structure and large furnace, to ensure the sufficient combustion, and the boiler could absorb the thermal expansion effectively. The large diameter boiler drum increases the radiant heating surface, to ensure the sufficient output.

7. Environmental protection

1) The biomass fuel do not content sulfur, do not pollute the environment, and the cost on biomass fuel is low.

2) The splayed wall and smoke outlet have the function of dust removal, decrease the concentration of smoke emission.

Technical Parameter

Model | Rated evaporation | Rated pressure | Thermal efficiency (%) | Fuel consumption (kg/h) | Overall Dimension L×W×H (mm) | Weight (ton) |

DZL1-0.7/1.0/1.25-T | 1 | 0.7/1.0/1.25 | 82 | ~200 | 5100×2200×3000 | 17 |

DZL2-0.7/1.0/1.25-T | 2 | 0.7/1.0/1.25 | 82 | ~400 | 5500×2300×3300 | 23 |

DZL4-1.25/1.6-T | 4 | 1.25/1.6 | 82 | ~800 | 6600×2600×3600 | 25 |

DZL6-1.25/1.6-T | 6 | 1.25/1.6 | 82 | ~1200 | 8200×2900×3800 | 40 |

DZL8-1.25/1.6-T | 8 | 1.25/1.6 | 82 | ~1600 | 8100×3100×3800 | 53 |

DZL10-1.25/1.6-T | 10 | 1.25/1.6 | 82 | ~2010 | Up 7700×3200×3600 Down 8600×3200×6735 | 72 |

Note: 1. Parameter is for reference only, if any changes should follow the factory technical data. 2. Our company can design boiler products based on customers’ requirement and different biomass fuels. | ||||||

Categories

Contact Us

Tel:+86 158 3808 8573

Fax :+86 371 5596 3948

Mobile:+86 158 3808 8573

E-mail: [email protected]

Skype: 15838088573

Whatsapp: +86-15838088573