Thermal Oil Boiler

Natural Gas LPG Fired Thermal Oil Boiler

- Rated power: 300,000-2,000,000 Kcal/H

- Pressure: 0.8Mpa

- Fuel: natural gas, LPG, etc.

- Application: Textile printing and dyeing, plastic and rubber,

- wood industry, building material, machinery industry, food industry, etc.

- INQUIRY

YY(Q)W series oil fired thermal oil boiler is an safe and energy saving boiler with working characteristics of low working pressure (0.8 MPa) and high temperature (330℃).

The heat carrier is heat conduction oil, the circulating pump force heat transfer medium circulating in liquid phrase, and transfer heat to heat user equipment, then return to the heating furnace for reheating. Jinzhen Boiler has a mature R&D and design team, could customize the boilers based on customers’ requirement.

Advantages

1. High thermal efficiency

The boiler is circulation heating in liquid phase, there is no heat loss leaded by condensing, thermal efficiency is high, and the boiler is very safe when operating.

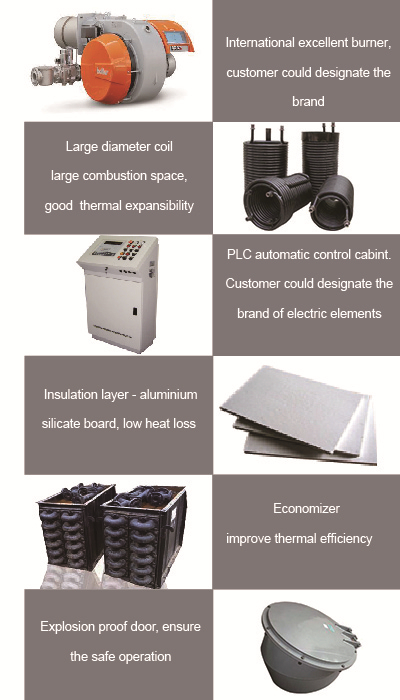

2) The boiler shell use aluminum silicate board for heat preservation, low heat loss.

3) By equipped with economizer, make full use of flue gas heat, decrease the exhaust smoke temperature.

2. Large combustion chamber

The boiler combustion chamber is composed with large diameter coil, enough fuel combustion space, sufficient combustion, high thermal efficiency. Moreover, the boiler adopts positive pressure combustion, improve the combustion efficiency.

3. Excellent coil design

The spiral pipes are made of small diameter multi-head steel tubes, good thermal expansibility, low stress, safe and reliable.

4. Sufficient output

The boiler adopts horizontal type three pass structure, improve the heat utilization efficiency. Large heating area, good heat transfer, achieve high thermal efficiency and sufficient output.

5. Multi-function safety explosion-proof equipment

Equipped with explosion proof equipment at the back of boiler, prevent deflagration in furnace, discharge high energy, to ensure the boiler operate safely and efficiently.

6. Perfect automatic control

The boiler adopts PLC full automatic intelligent control cabinet and interlock protect system, has the protect function on oil temperature, medium temperature, pressure, etc, adjust conveniently.

7. Convenient installation

The boiler is package boiler, compact structure, covers small area, convenient for installation and maintenance.

Technical Parameter

| Model | Rated power(KW) | Design pressure (Mpa) | Medium outlet temperature(℃) | Thermal efficiency (%) | Overall dimension L×W×H(mm) | Weight (t) |

| YY(Q)W-120Y(Q) | 120 | 1.1 | ≤350 | 75 | 1600×1020×1520 | 1.5 |

| YY(Q)W-1000Y(Q) | 1000 | 1.1 | ≤350 | 85 | 3300×1670×2486 | 5 |

| YY(Q)W-2400Y(Q) | 2400 | 1.1 | ≤350 | 85 | 5080×2200×3180 | 9.8 |

| YY(Q)W-3000Y(Q) | 3000 | 1.1 | ≤350 | 85 | 5983×2420×3404 | 15.5 |

| YY(Q)W-4700Y(Q) | 4700 | 1.1 | ≤350 | 85 | 7285×2570×3760 | 21.5 |

| YY(Q)W-6000Y(Q) | 6000 | 1.1 | ≤350 | 85 | 7800×3050×3800 | 25 |

| YY(Q)W-7000Y(Q) | 7000 | 1.1 | ≤350 | 85 | 8200×3050×3800 | 27.5 |

| YY(Q)W-10000Y(Q) | 10000 | 1.1 | ≤350 | 85 | 10000×3500×4000 | 32 |

| Notes: Parameter is for reference only,if any changes should follow actual drawings. | ||||||

Application

Owing to its characteristics of high heating temperature, low working pressure, and energy saving, the oil fired thermal fluid heater could be widely used in a variety of industrial heating process.

1) Textile industry - dyeing machine, drying rooms, high temperature machine, resin setting machine.

2) Food industry - cooking, drying, vegetable oil refining.

3) Chemical industry - oil chemistry, polymer industry, reaction tanks, distillation, concentration.

4) Plastics industry - plastics fired, extruded shape.

5) Rubber industry - hot press, hot extent, extrusion, vulcanization molding, injection, etc.

6) Paper industry - drying, corrugated paper processing, calender, glue roller.

7) Wood industry - hot processing, heat setting.

8) Machinery industry - drying, assembly processing

9) Building materials industry - plasterboard drying, asphalt heating, emulsified asphalt, asphalt concrete, concrete component maintenance, etc.

10)Synthetic fiber industry: polymerization, melting, spinning, extension, dry

Categories

Contact Us

Tel:+86 158 3808 8573

Fax :+86 371 5596 3948

Mobile:+86 158 3808 8573

E-mail: [email protected]

Skype: 15838088573

Whatsapp: +86-15838088573